We serve customers across Ohio and neighboring states with an emphasis on responsible forestry and consistent supply. Therefore, whether you’re flooring a home, building furniture, or repairing trailers, our hardwood products come from forests managed for long-term health and regeneration. Explore the categories below to learn more about our most requested materials and their applications.

What Makes Our Flooring Blanks Different

- Cut for stability and yield: Plainsawn for figure; rift & quartersawn on request for straighter grain and reduced movement.

- True kiln-drying: Boards are meter-checked to match interior moisture targets before shipment, reducing cupping and gapping.12

- Species matched to use: White Oak, Hard Maple, Black Walnut, and Hickory are stocked regularly; others available by arrangement.

- Flooring-ready format: Jointed, edged blanks sized for tongue-and-groove or square-edge milling lines.

- Regional sourcing: Shorter supply chains, predictable lead times, and traceable logs from responsibly managed forests.4

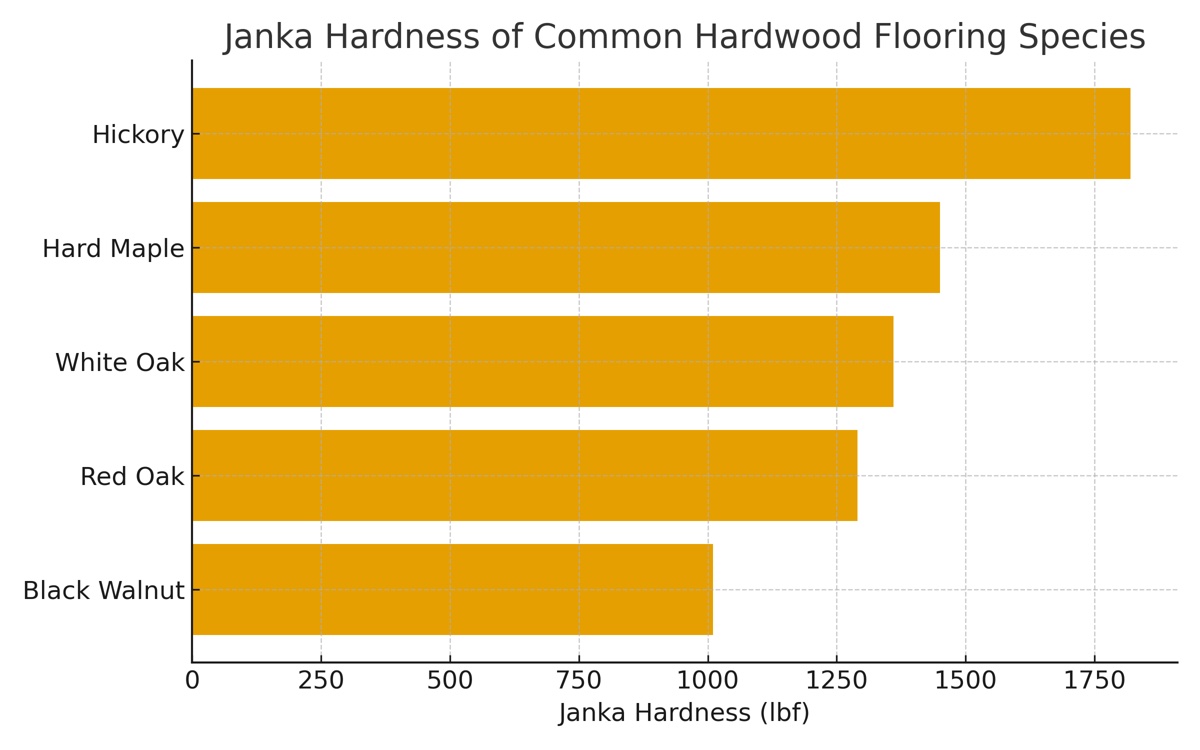

Relative Hardness of Common Hardwood Flooring Species

The Janka Hardness Scale measures how resistant each wood species is to denting and wear. These values help compare durability for flooring selection.1

As shown above, Hickory ranks among the hardest domestic hardwoods, followed by Maple and White Oak. Walnut provides warmth and stability with moderate hardness, while Red Oak remains the benchmark for balance between cost and performance.

Species Guidance and Common Uses

- White Oak

- Classic durability with closed pores that finish cleanly; excellent for both traditional and modern interiors.

- Hard Maple (Sugar Maple)

- Light tone and high hardness for gyms or high-traffic spaces; acclimate carefully before install.1

- Black Walnut

- With rich color and consistent stability, walnut is ideal for accent floors or mixed-species layouts.

- Hickory

- Exceptional hardness with natural character; specify color sort when uniformity is required.1

For other hardwood options such as live-edge slabs or custom lumber, see our Hardwood Products Overview.

Dimensions, Tolerances, and Milling Window

Moisture & Acclimation Targets for Ohio Interiors

For conditioned interiors in this region, solid hardwood floors perform best when installed between 6–9% moisture content (MC). The table below summarizes practical EMC targets for typical Ohio conditions.235

Use this table to match our shipped MC targets to the indoor conditions of your project before milling or installation.

| Season | Typical Indoor RH | Target Flooring MC | Notes |

|---|---|---|---|

| Winter (heated) | 30–40% | 6–7.5% | Lower EMC — expect slight seasonal gaps. |

| Spring/Fall | 35–45% | 6.5–8% | Balanced conditions; aim mid-range. |

| Summer (air-conditioned) | 40–50% | 7–9% | Higher EMC — stabilize humidity before install. |

Acclimate blanks in the conditioned space with HVAC running and subfloors at the same moisture equilibrium as the finished room.5

Sustainability and Regional Advantage

Every flooring blank originates from selectively harvested stands managed for long-term health and regeneration. We work directly with landowners committed to sustainable forestry and habitat conservation.4

All hardwoods are grown and processed within the Ohio Valley region, minimizing transport distance and supporting local forestry economies. This regional model keeps the environmental footprint of every plank small while maintaining full traceability from stump to shipment.

Subfloors, Finishes, and Care

- Subfloor readiness: Flat, dry, and within the target MC range before fastening.5

- Finishing: Test color and sheen before production; film finishes add wear resistance, while oils highlight grain.

- Maintenance: Keep indoor humidity stable year-round; follow manufacturer guidance for cleaning and recoating.

Ordering, Lead Times, and Packaging

Provide your target square footage, species, thickness, and profile. We’ll confirm availability and kiln schedules before production. Typical lead times range from two to four weeks depending on species and volume. Minimum orders start at approximately 500 board feet, with smaller runs available for regional partners.

Blanks are stickered, strapped, and wrapped for transport stability. Meter readings are recorded at load-out for reference upon delivery.

Contact the Experts

For information on species availability, drying schedules, or pricing, contact the experts at Ohio Timber Works. Our team can help determine the right hardwood flooring blanks for your application. To view related products, visit our Hardwood Products Overview page.

References

- U.S. Forest Products Laboratory. Wood Handbook: Wood as an Engineering Material (latest ed.). Forest Service, USDA. Available at: https://www.fpl.fs.usda.gov/documnts/fplgtr/fpl_gtr190.pdf

- Forest Products Laboratory. Equilibrium moisture content (EMC) relationships and shrink/swell data for hardwoods. See Reference 1.

- Forest Products Laboratory. Species properties (Janka hardness, shrinkage coefficients) for White Oak, Maple, Walnut, and Hickory. See Reference 1.

- U.S. Forest Service, Forest Inventory & Analysis (FIA). Forests of Ohio factsheets (latest release). Treesearch index: https://www.fs.usda.gov/research/treesearch

- National Wood Flooring Association (NWFA). Technical guidance for site conditions, acclimation, and installation practice. Available at: https://nwfa.org/technical-standards/