Logging Equipment and Processes Part 1 highlights the diverse methods, equipment, and workflows used in timber harvesting. Each approach offers unique benefits and costs to landowners, logging companies, and the forest ecosystem.

While it is impossible to say that one method or another is superior to all of the others, a little education goes a long way in deciding which logging process is right for your standing timber.

Various Logging Equipment and the Consequences

The width of roads and paths utilized to harvest your timber will be directly related to the size of the equipment used by the logging company.The equipment’s features, like wheels or tracks, cable-wenches, or grapples, directly affect the condition of your timber land.

Logging Equipment and Processes Part 1

-

While some logging companies are concerned entirely with speed and efficiency, Timber Works works hard to achieve an efficient logging campaign while treating your woods and land with respect and care.

Regardless of the logging method employed to harvest a stand of timber, periodic logging is an integral part to sound forest management and does not need to occur at the cost of ecological health.

-

- Felling: Cutting trees at the stump

- Processing: Removing branches and limbs and cutting the stem into appropriate lengths

- Extraction: Moving logs from the woods to a landing site

- Loading: Loading logs or chips onto a truck

- Hauling: Delivering loaded forest products to the mill

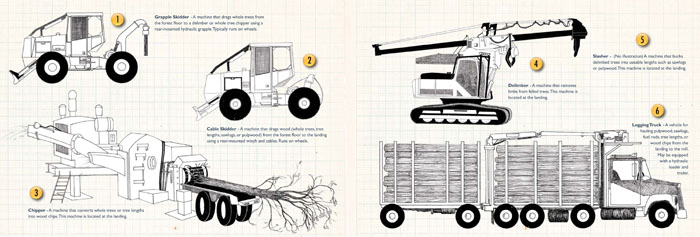

While the methods and processes of logging varies, there is a number of standard machines that appear on most jobs. Included among this equipment is:

1. Grapple Skidder: A machine that drags whole trees or whole tree stems from the forest floor to a landing site.

2. Cable Skidder: Cable skidders drag whole trees or tree stems from the forest floor using a heavy-duty rear mounted wench.

3. Chippers: Not all logging companies use chippers, but those that do process limbs or trees into uniform chips for mills.

4. Delimber: Located at the landing, delimbers remove limbs from whole trees before further processing in commercial logging operations.

5. Slasher (not pictured): Sometimes known as buck saws, slashers automatically cut tree stems into appropriate lengths for loading and hauling.

6. Logging Truck: A vehicle designed for the transportation of logs and other forest products. Vehicles may be equipped with a hydraulic loader and additional trailer.

Logging Equipment and Processes Part 1

“The equipment and processes utilized in the logging application chosen for your standing timber can significantly impact how your woods are left when the logging company departs. Therefore, a logging company will only leave a footprint as big as their equipment. However, for logging methods such as clear-cutting, this may be of little consequence to the finished product. On the other hand, the result from other, less invasive styles of logging will be directly influenced by the equipment used by the logging company. Consequently, choosing the right equipment is essential. Moreover, careful planning can further minimize the impact. In contrast, poorly chosen methods can lead to unnecessary damage. Ultimately, this highlights the importance of thoughtful decision-making in logging operations.

The second installment of this series will go into further detail about these differences while helping to inform you, the land owner, of the various outcomes from logging activity available to you including the differences between clear cutting, selective harvesting, tree length removal and other nuances that are often not fully explained to a land owner prior to beginning a timber harvest.